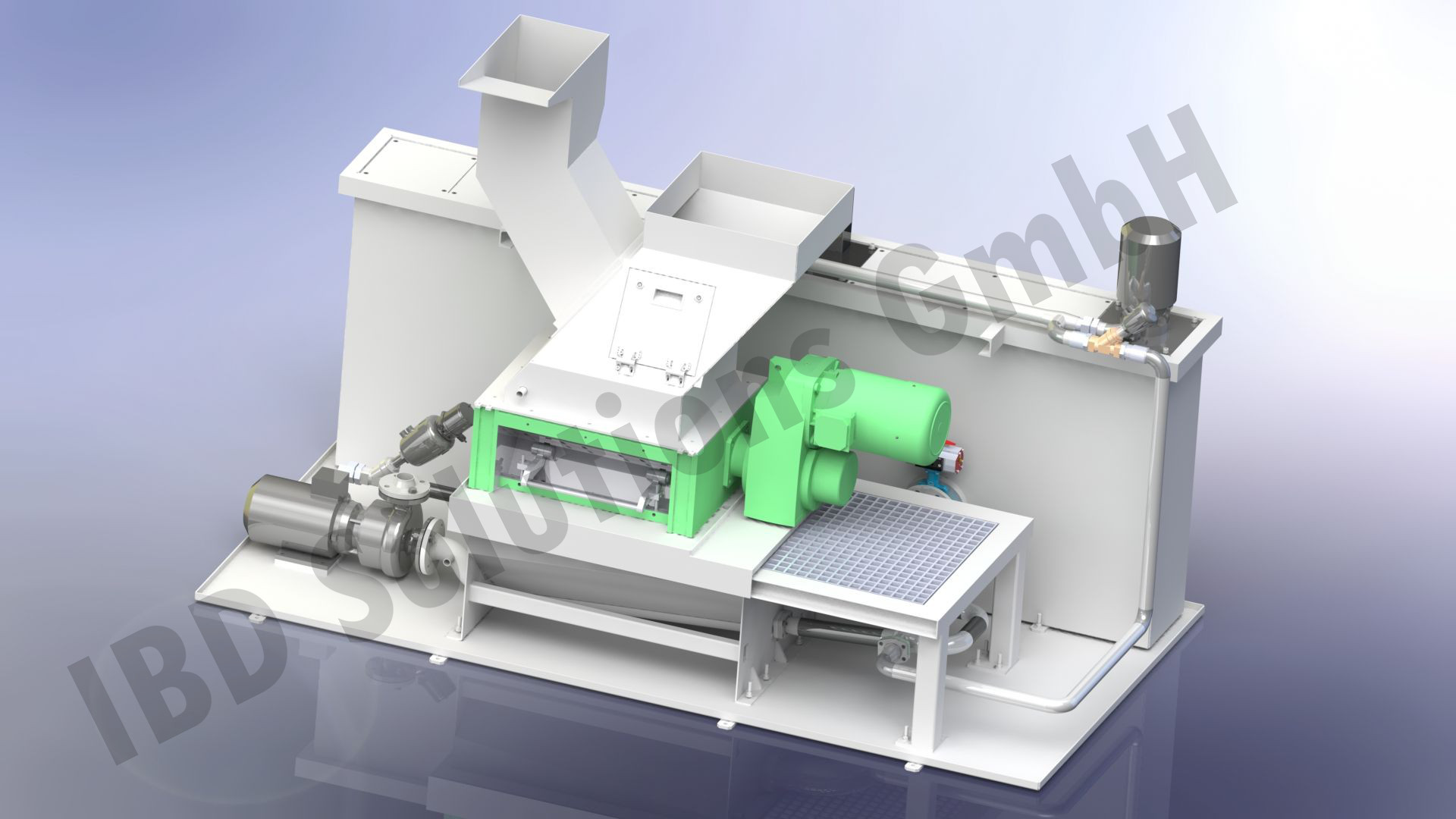

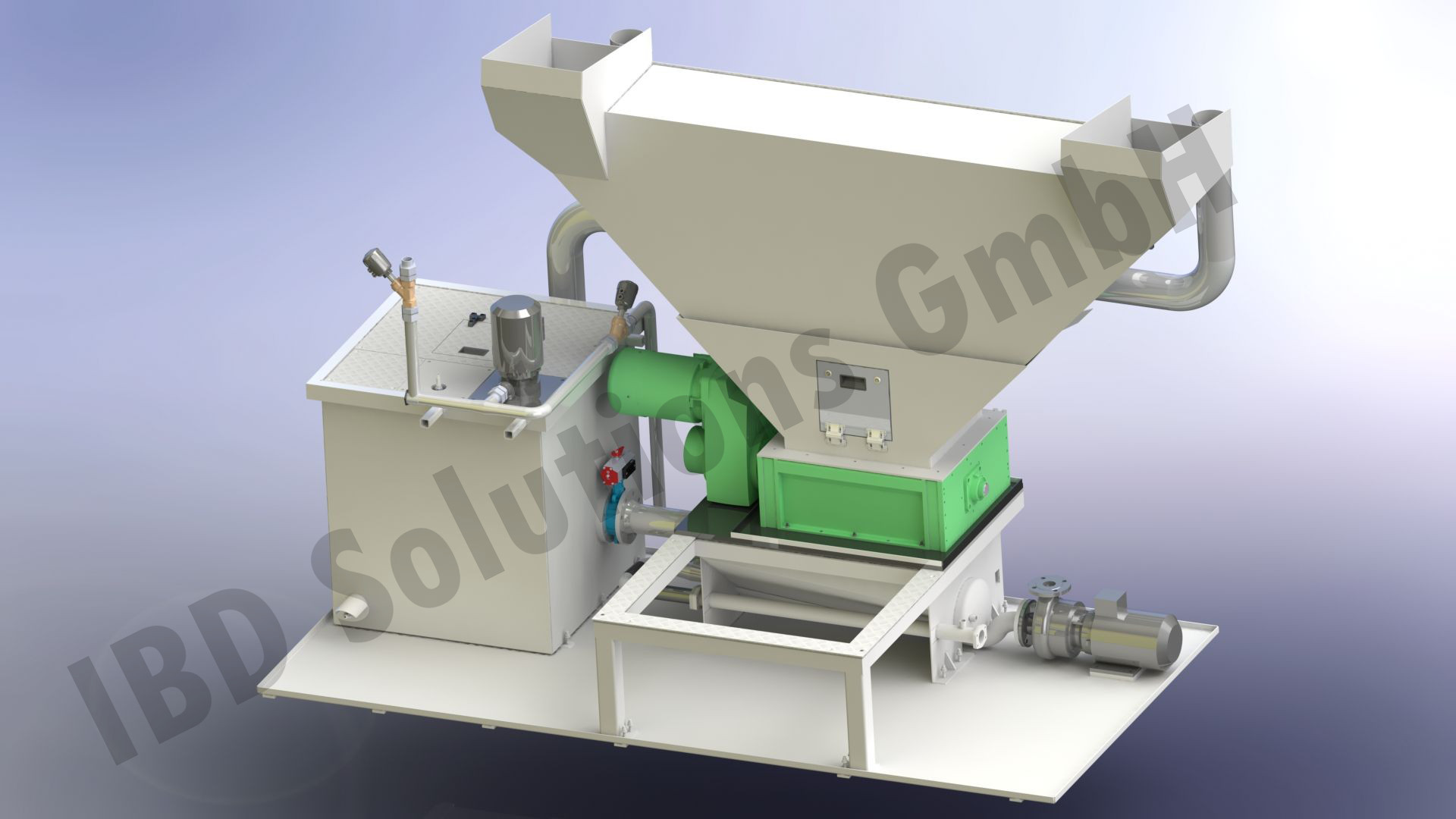

Project 4

CENTRAL COOLANT LUBRICANT SUPPLY SYSTEM WITH CHIP TRANSPORT

The chips / bunches of chips from the machine tool are transported to the pump station via a conveyor belt. The pump station processes the chips in such a way that they can be conveyed with the coolant lubricant adhering to them via a pipe system to the central system.

In the central system the chips are separated from the coolant lubricant and then dried with the aid of a centrifuge.

The coolant lubricant is worked up with a lamella separator and held in the clean tank. Supply pumps feed the central pipe system for supplying the individual machine tools.

System type:

S4000-2

Application:

turning / milling

Volumetric flow:

10.000 l/min

Supply pressure:

2 – 6 bar – able to be set via a control system

Guaranteed filtration fineness:

20 µm

Special features:

Chip transport | centrifuge | redundant preliminary chip removal | two-fold preliminary chip removal for the type-sorted working up of the different material types

ADVANTAGES OF THE SYSTEM:

- Conveying of chips with lengths of up to 100 mm. Thereby elimination of the cost for the comminution process previously necessary

- Exact setting of the amount of concentrate by means of an automatically functioning, electronic refractometer

- Reduction of operating costs

- Reduction of costs through reusing and central maintaining of the coolant lubricant

- Reduction of manpower costs through elimination of manual chip handling

- Considerable lengthening of the service life of the coolant lubricant

- All separate coolant lubricant supply pumps and filtration systems within the manufacturing area are dispensed with

- Significant gaining of production space through elimination of chip containers and long transport paths

- Increases to the level of cleanliness in the production