Project 2

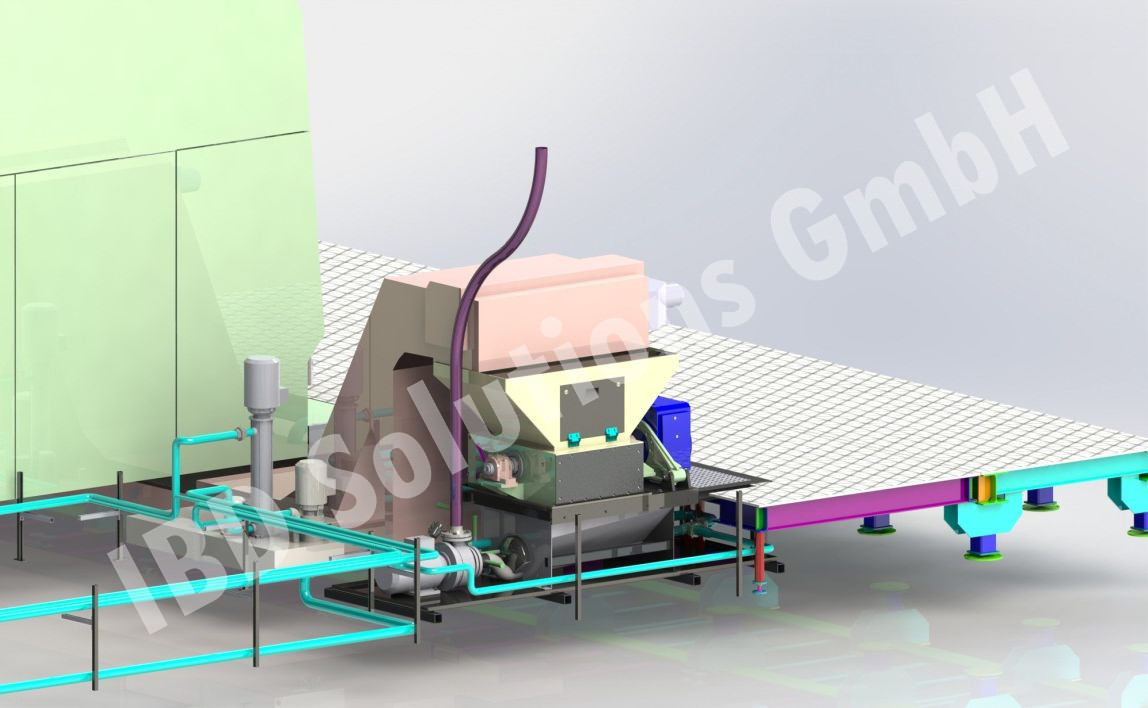

CENTRAL COOLANT LUBRICANT SUPPLY SYSTEM WITH CHIP TRANSPORT

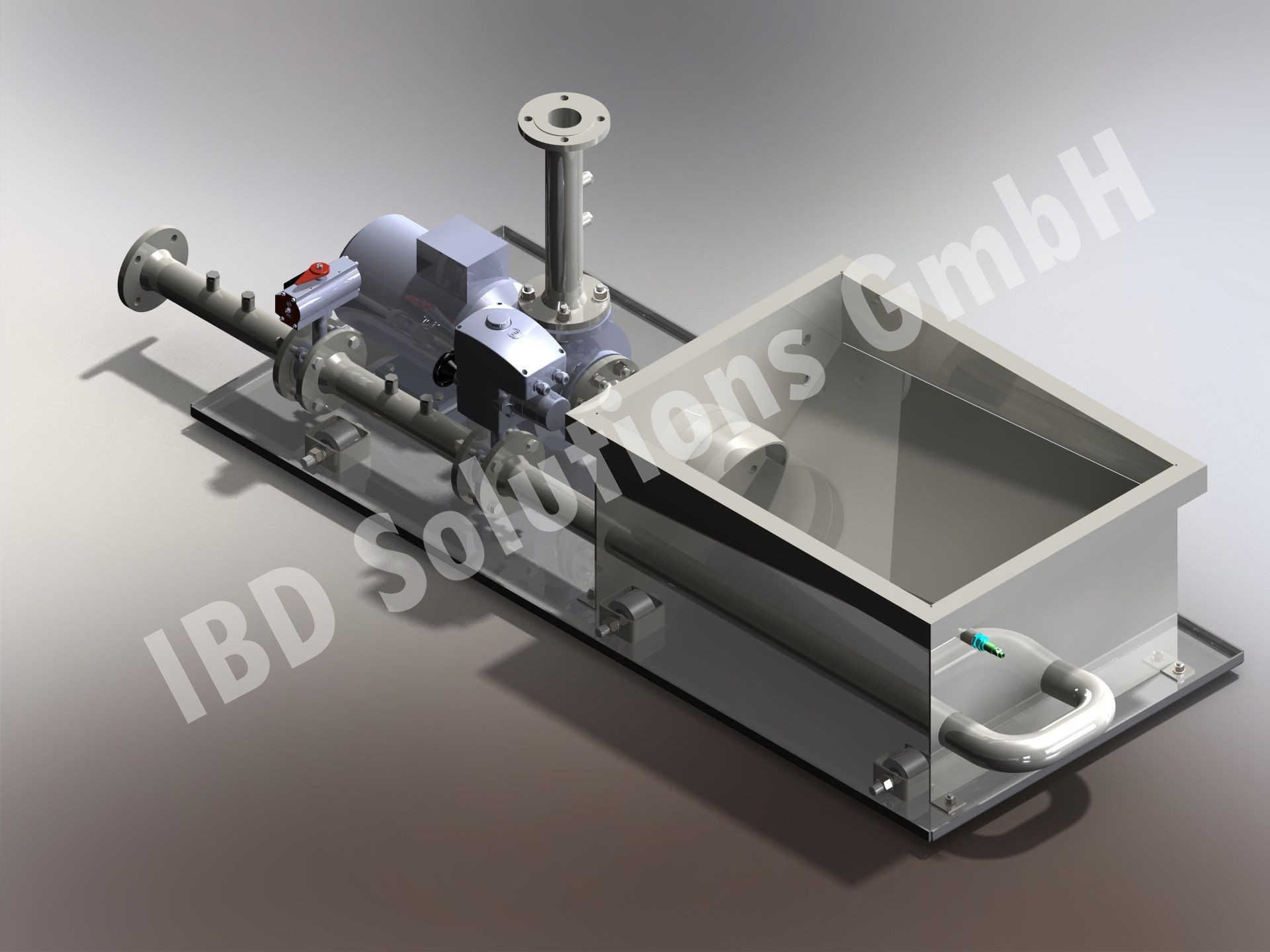

The chips / bunches of chips from the machine tool are transported to the pump station via a conveyor belt. The pump station processes the chips in such a way that they can be conveyed with the coolant lubricant adhering to them via a pipe system to the central system.

In the central system the chips are separated from the coolant lubricant and then briqueted with a briqueting system.

The coolant lubricant is worked up with a lamella separator and held in the clean tank. High and low pressure supply pumps feed the central pipe system for supplying the individual machine tools.

System type:

S4000-2

Application:

turning / milling

Volumetric flow:

8.000 l/min

Supply pressure:

Low pressure 2 – 6 bar – able to be set via a control system

High pressure 40 – 80 bar – able to be set via a control system

Guaranteed filtration fineness:

20 µm

Special features:

Stage-wise construction | conveying of tough stainless steel chips | briqueting system | cooling system | high and low pressure supply

ADVANTAGES OF THE SYSTEM:

- Conveying of chips with lengths of up to 100 mm. Thereby reduction of the cost for the comminution process previously necessary

- Conversion of the waste materials into reusable materials / reduction of the disposal costs / increasing of the sales revenue from the materials as recovered

- Reduction of operating costs

- Reduction of costs through reusing and central maintaining of the coolant lubricant

- Considerable lengthening of the service life of the coolant lubricant

- Reduction of the expenditure for cooling through the central high pressure supply system

- All separate coolant lubricant supply pumps and filtration systems within the manufacturing area are dispensed with

- Gaining of production space

- Increases to the level of cleanliness in the production