Project 1

CENTRAL COOLANT LUBRICANT SUPPLY SYSTEM WITH HIGH AND LOW PRESSURE

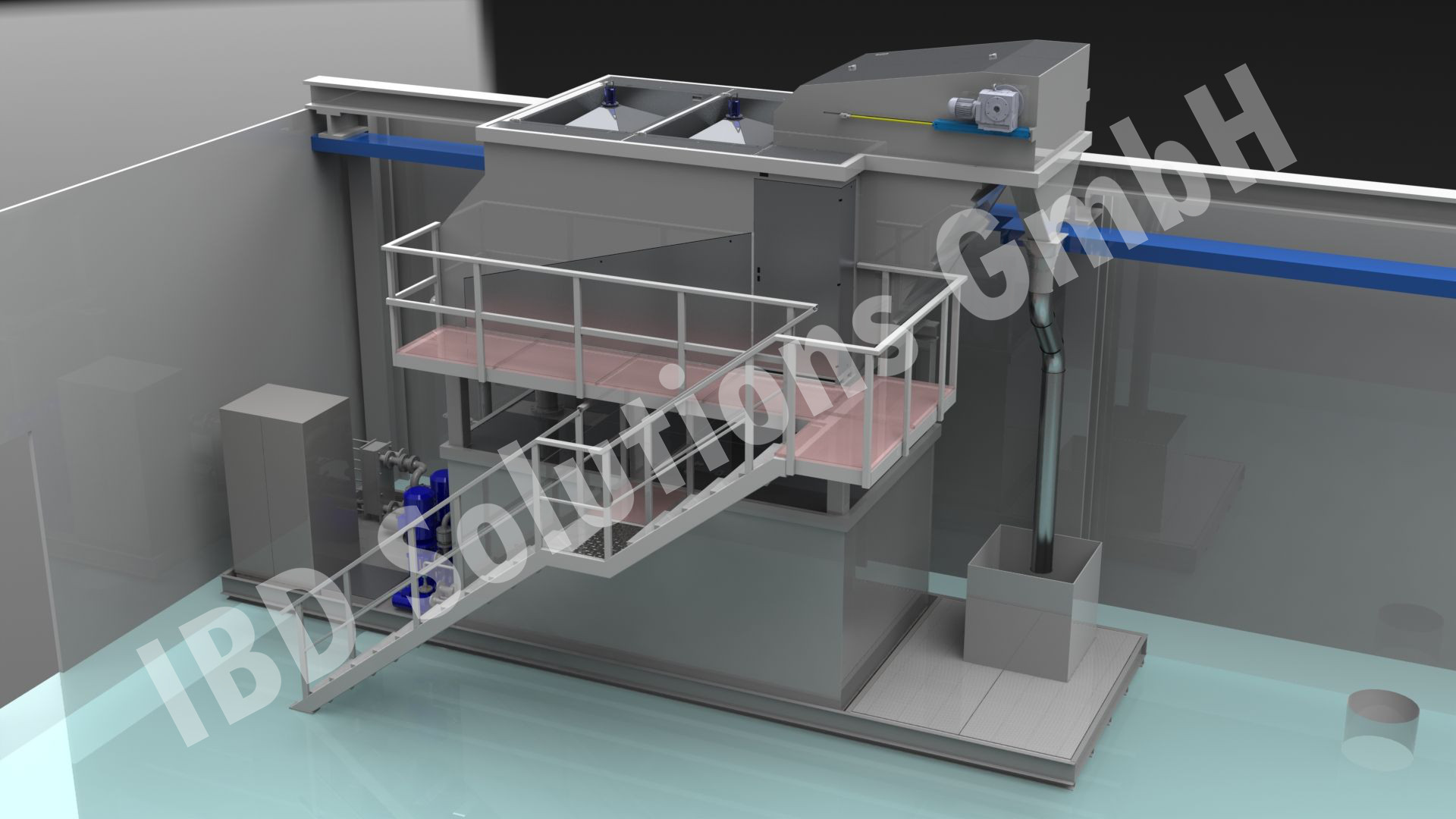

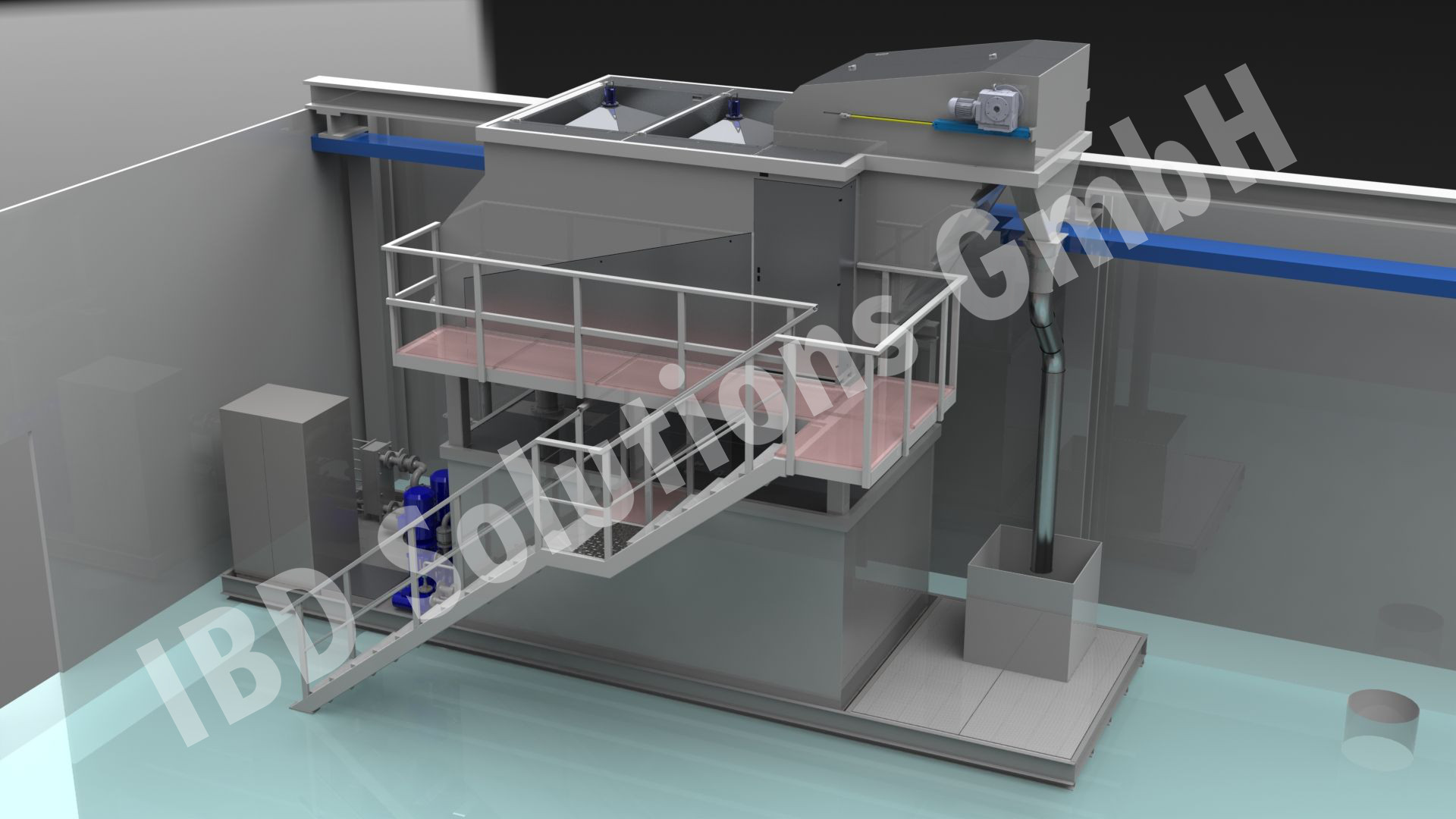

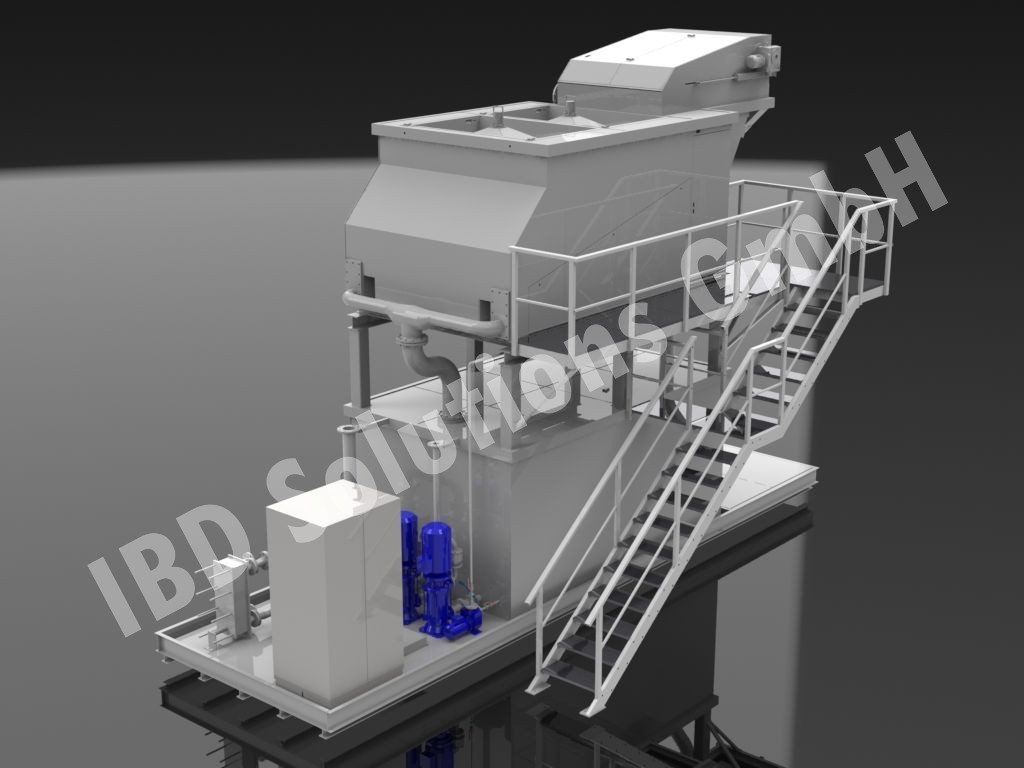

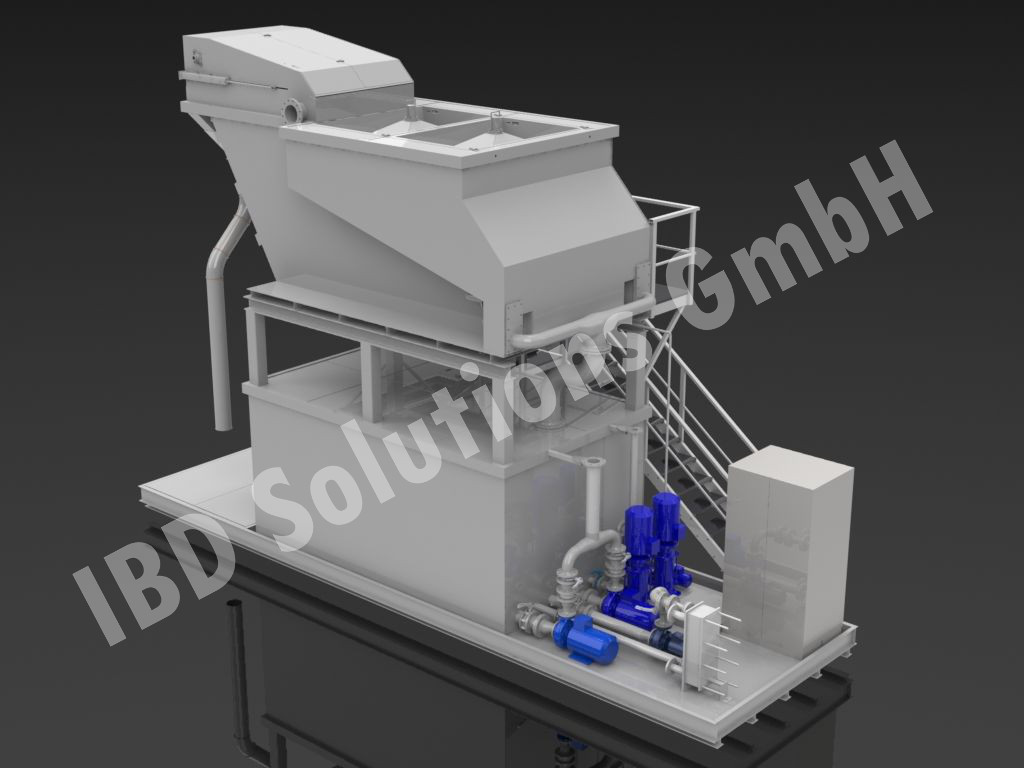

The coolant lubricant contaminated with solids, chips and other contamination is fed with the aid of pumping stations through a pipe system to the inlet of the filter system. After having been separated off, the contaminants are carried out with the scraper conveyor installed in the filter system and transported to the containers for disposal.

The supply pumps take the cleaned coolant lubricant from the clean tank and supply the machine tools with high and low pressure. The coolant lubricant in the clean tank is brought to the required temperature with a heat exchanger.

The stage-wise construction design gives a compact form so that the filter system can be integrated into the manufacturing process on an ancillary area.

System type:

S3000-2

Application:

turning / milling

Volumetric flow:

3.000 l/min

Supply pressure:

Low pressure 2 – 6 bar – able to be set via a control system

High pressure 10 – 25 bar – able to be set via a control system

Guaranteed filtration fineness:

20 µm

Special features:

Stage-wise construction | cooling system | high and low pressure supply

ADVANTAGES OF THE SYSTEM:

- Reduction of operating costs

- Reduction of costs through reusing and central maintaining of the coolant lubricant

- Considerable lengthening of the service life of the coolant lubricant

- Energy-saving pressure generating system

- Completely closed system

- All separate coolant lubricant supply pumps and filtration systems within the manufacturing area are dispensed with

- Gaining of production space

- Increasing of the level of cleanliness in the production