Central Systems

CENTRIFUGES

Downstream centrifuges dry metal chips that have been eliminated and feed the separated off coolant lubricant back into the preparation system.

The centrifuges can be integrated into the central system.

BRIQETING SYSTEMS

A further possibility is the briqueting of materials that have been separated off. Grinding sludges as well as also chips are compacted through the briqueting. In this way the volume of the residues as well as also their residual moisture content are significantly reduced. This simplifies transport paths, coolant lubricant is recovered and revenue can be obtained from the residues.

The briqueting systems can be integrated into the central system.

WEIGHING SYSTEMS

With the aid of weighing systems the weight – for example of containers – can be determined; the system can then be informed and react appropriately.

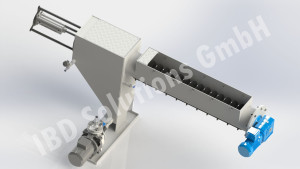

SCREW CONVEYORS

The screw conveyors are mounted directly beneath the outlet point of the filter system. They collect grinding sludges and chips and transport these to systems for processing them, e.g. to centrifuges, briqueting systems etc.

SLUDGE PRESSES

The volume and residual moisture content of grinding sludges are reduced by pressing. This simplifies transport paths and enables coolant lubricant to be recovered. The sludge presses are mounted directly beneath the outlet point of the filter system.

It is a matter here of a relatively simple and cost-favourable system that – with little expenditure – is highly efficient.

CENTRAL CONVEYOR BELTS

Conveyor belts are used to transport solid materials as well as also sludges. It is a matter here of modular systems which can be adapted individually to meet particular customer requirements in a simple manner through the selection of the individual components. Even a retrospective modification of a conveyor belt into a scraper conveyor is possible. Different modules permit a system that cleans itself automatically to be configured.