Automation Technologies

ELECTRICAL CONTROLS / VISUALIZATION

Our systems are equipped with the most modern control systems. Communication facilities within each automation level also take into account industry standard 4.0 for the future.

Remote accessing via the Internet in order to ensure the highest levels of availability are a standard matter for us with IPC systems, whereby the most stringent security standards are maintained in order to exclude the possibility of accessing by unauthorized persons.

Different controls are used, the selection being oriented on the complexity of the particular system.

The following control is used for simple automation applications:

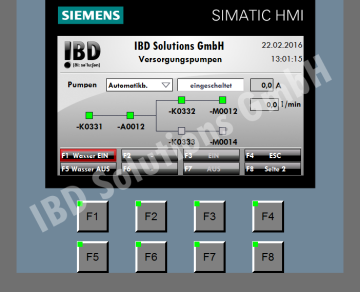

S7-1500 WITH KP400 COMFORT

Connection voltage:

Control voltage:

Siemens PLC control:

Operator display:

400 V / 3 Ph / 50 Hz / N / PE

24 V DC

S7-1500, CPU 1511-1 PN

KP400 Comfort, 4″

- Intuitive operation via menus

- Password check for changes to parameters

- Error message processing with history records

- Internal communication via Ethernet protocol

- Analog value processing of levels

For more demanding requirements or with more complex systems we use the following control:

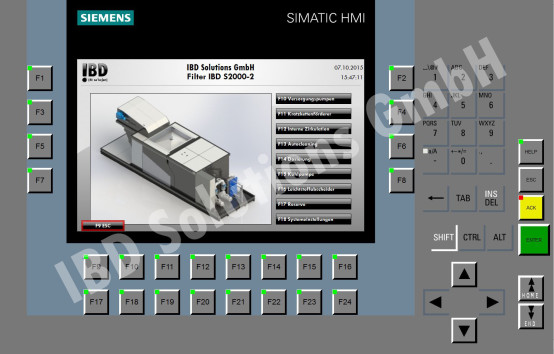

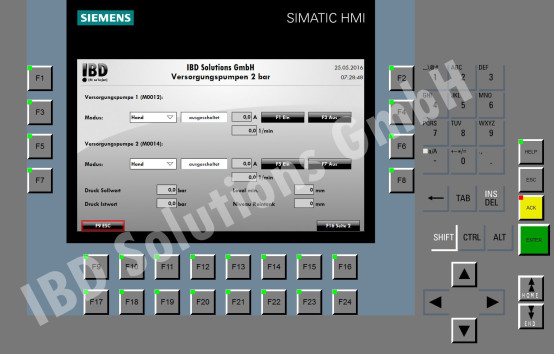

S7-1500 WITH KP700 COMFORT

Connection voltage:

Control voltage:

Siemens PLC control:

Operator display:

400 V / 3 Ph / 50 Hz / N / PE

24 V DC

S7-1500, CPU 1511-1 PN

KP700 Comfort, 7″

Performance data as KP400 Comfort, but:

- 7“ display with more space for visualization

- Graphic representation of analog values such as levels, pressure, temperature etc.

Depending on the customer’s wishes, more operator-friendly and powerful controls can be used.

In the upper performance class we use systems on the basis of an industrial PC with touch display.

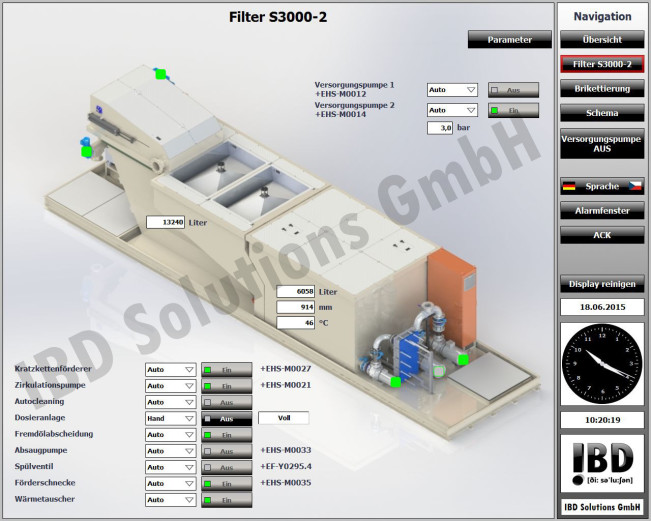

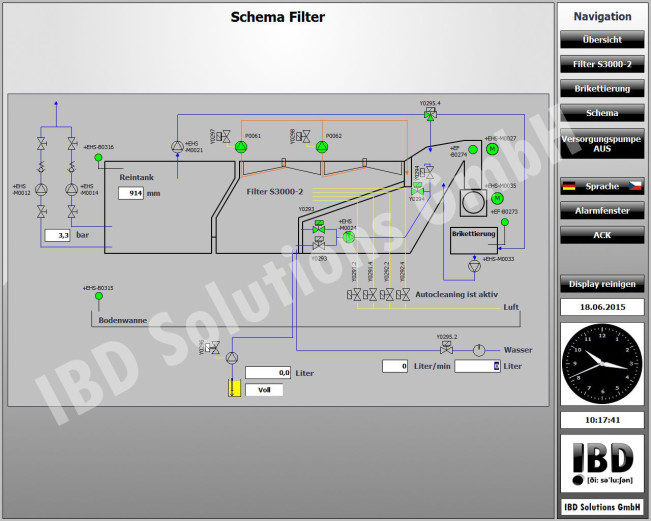

S7-1500 WITH IPC AND WINCC VISUALIZATION

Performance data as KP700 Comfort, but:

- Large 19“ touch display

- Windows operating system with Siemens WinCC visualization

- Ability for the system to be used as a programming device for all the systems installed

- Elaborate graphic representation of analog values such as levels, pressure, temperature etc.

- Opportunity for Office applications (e.g. Word, Excel, etc.) to be integrated

- Remote maintenance via Internet